VIEW OUR CATALOG

What are Cast Bronze Bushings?

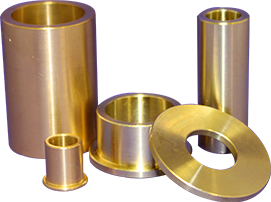

A bushing, also known as a plain bearing, is designed to reduce friction between two surfaces as they slide against one another. In machines and equipment with rotating or sliding shafts, bushings are used to enhance overall efficiency and longevity while reducing noise and vibration. They generally come in the following two styles:

- Sleeve bushings. Sleeve bushings are cylindrical in shape, featuring straight inside and outside diameters.

- Flanged bushings. Flanged bushings feature a flange that extends radially outward from one end. The purpose of the flange is to act as a thrust face at one end of the bushing also preventing any axial movement.

As friction-reducing components, it is essential that bushings are constructed from wear-resistant materials that provide good sliding properties. While bushings can be fabricated from a variety of plastics and metals, bronze provides several distinct advantages over alternative options in heavy-load applications. As an inherently moldable and easy-to-machine material, bronze is well-suited for achieving a range of bushing designs.

The bronze alloy used in cast bronze bushings undergoes a continuous or centrifugal casting process, giving the metal a finer grain structure and improved mechanical properties. The bronze alloy cast bar is then cut and processed into the finished bushing using a computer numerical control (CNC) lathe or other precision machining method. Cast bronze bushings exhibit excellent structural strength, durability, and resistance to compressive forces, making them well-suited for harsh, high-wear applications. They can also withstand high temperatures without losing their strength.

Applications of cast bronze bushings include:

- Heavy duty equipment. The hardness and impact resistance of cast bronze bushings make them ideal for use in a range of construction, agricultural, and industrial equipment requiring high reliability in harsh environments.

- Hydraulic machinery. With their heat resistance and exceptional mechanical properties, bronze cast bushings are perfect for supporting components in the cylinders and motors of hydraulic machinery.

- Power transmission components. Cast bronze bushings help improve the efficiency and performance of critical components used in power transmission applications.

- Aerospace systems. Cast bronze bushings help reduce weight and enhance the performance of mechanical moving parts in various aircraft systems.

- Manufacturing tools and equipment. The bronze alloys used in cast bronze bushings give them the strength and wear-resistance to support components in stamping dies, presses, and other tools and equipment used in the manufacturing industry.

A thrust washer is a flat, disc-shaped bearing that is placed between a rotating component and stationary component in a rotary assembly. Designed to control axial motion, thrust washers keep components aligned along a shaft by providing them with a surface to run up against. They also help prolong the life of these components by protecting them from excess wear during use. For certain applications, grooved raceways can be integrated into the washer’s design to facilitate the movement of axial forces in one direction.

Available in a range of thicknesses, sizes, and styles, cast bronze thrust washers are used in a wide variety of high-wear applications. Some examples include:

- Automotive systems. Cast bronze thrust washers are heat-tolerant and corrosion-resistant, making them ideal for use in transmissions, axle assemblies, motors, and other automotive systems requiring smooth and low-maintenance operation.

- Oil and gas equipment. With their exceptional wear resistance, cast bronze thrust washers are well-suited for supporting and protecting components in oil drilling equipment.

- Marine and defense equipment. The high strength and corrosion resistance of cast bronze thrust washers allow them to provide reliable performance in marine and defense equipment used in harsh and unpredictable environments.

- Industrial machinery. Cast bronze thrust washers exhibit the wear resistance and load-bearing properties to handle the specific demands of various industrial machinery, including automation equipment, mechanical and hydraulic presses, hauling and lifting devices, and more.

VIEW OUR CATALOG

Our Cast Bronze Bushings and Thrust Washers

C93200 (SAE 660) Cast Bronze Bushings

The C93200 (SAE 660) series of cast bronze sleeve and flanged bushings are made from an all-purpose leaded bronze alloy with excellent antifriction properties and machinability. These bushings exhibit exceptional wear resistance, durability, and shock-loading capabilities, allowing them to provide reliable performance across a long lifespan. Physical properties include:

- 35,000 psi minimum tensile strength

- 20,000 psi minimum yield strength

- 10% minimum elongation in 2″

- Brinell Hardness (500 kg load): 65 typical

- Machinability Rating: 70

- Minimum Operating Temperature: -450°F

- Maximum Operating Temperature: 500°F

- P Value Max 4,000

- V Value Max 750

- PV Value Max 75,000

Bushings & Bars offers the following C93200 (SAE 660) products:

C87850 (ECO Bronze) Cast Bronze Bushings & Thrust Washers

The C87850 (ECO Bronze) series of cast bronze bushings and thrust washers provides an eco-friendly, lead-free alternative to the C93200 (SAE 600) leaded bronze series. ECO Bronze is an RoHS- and REACH-compliant alloy that has been tested through multiple independent laboratories and confirmed to be free of lead, arsenic, and bismuth. In addition to being environmentally safe and cost-effective, ECO bronze is proven to be equal to or better than traditional alloys in terms of quality and performance. Other beneficial properties of this material include:

- Excellent machinability

- Non-galling

- Lightweight

- Tolerant of high temperatures

- Excellent impact and compressive strength

- Resistant to dezincification and stress corrosion

- 100% recyclable

These properties make ECO Bronze cast bronze bushings and thrust washers perfect for meeting the strict safety and/or environmental regulations of the energy, marine, construction, medical, and food and beverage industries.

Mechanical properties of the ECO BRONZE C87850 series include:

- 65,000 psi tensile strength (minimum)

- 25,000 psi yield strength (minimum)

- 8% elongation in 2″ (minimum)

- Brinell Hardness (500 kg load): 103 typical

- Machinability Rating: 70

- Minimum Operating Temperature: -400°F

- Maximum Operating Temperature: 400°F

- P Value Max 4,400

- V Value Max 450

- PV Value Max 100,000

Bushings & Bars offers the following C87850 (ECO Bronze) cast bronze products:

ToughMet (C96900) Cast Bronze Bushings & Thrust Washers

The ToughMet (C96900) series of cast bronze bushings and thrust washers are made from a continuous-cast, spinodally hardened alloy with high tensile strength and excellent machinability. This alloy exhibits excellent galling, corrosion, and wear resistance, allowing bushings and thrust washers to last longer and carry higher loads. ToughMet bushings and thrust washers provide performance advantages in a range of demanding industries, including:

- Industrial

- Mining

- Aerospace

- Automotive

- Heavy equipment

- Off-road

- Oil and gas

- Drilling hardware

Mechanical properties of the ToughMet (C96900) series include:

- 110,000 psi tensile strength

- 105,000 psi yield strength

- 4% elongation

- Rockwell C 32 typical

- Machinability Rating: 8

- Minimum Operating Temperature: -450°F

- Maximum Operating Temperature: 550°F

- P Value Max 20,000

- V Value Max 500

- PV Value Max 275,000

The ToughMet series of bushings and thrust washers offers the highest PV rating in the Bushings & Bars catalog. Products include:

Partner with Bushings & Bars

With their high strength and durability, cast bronze bushings and thrust washers help prolong and enhance the performance of oil and gas equipment, aircraft engines, industrial machinery, and other critical, high-wear systems. Working closely with trusted U.S. manufacturers, Bushings & Bars sources high-quality cast bronze bushings and thrust washers that are carefully matched to the customer’s specific needs. Our vast inventory of products gives us the versatility to provide optimized solutions for customers from a wide range of industries.

To learn more about our product selection and how we can help you find the right solution for your application, please contact us today.