10 Reasons Why High-Quality Bushings for Industrial Applications Improve Durability & Efficiency

Comments Off on 10 Reasons Why High-Quality Bushings for Industrial Applications Improve Durability & Efficiency10 Reasons Why High-Quality Bushings for Industrial Applications Improve Durability & Efficiency

When it comes to optimizing industrial machinery, choosing the right components is critical for ensuring efficiency, reducing wear and tear, and minimizing downtime. Among these components, high-quality bushings for industrial applications play a significant role in boosting overall machinery performance. Bushings reduce friction between moving parts, leading to smoother operation and increased lifespan for your equipment. In this comprehensive guide, we’ll explore how investing in premium bushings enhances durability and efficiency, while providing actionable insights for selecting the best materials for your specific industrial needs.

Table of Contents

- Introduction: What Are Bushings and Why They Matter?

- The Importance of High-Quality Bushings in Industrial Applications

- Different Types of Bushings and Their Uses

- Why Durability Should Be Your Top Priority

- Material Selection: Which Bushing Is Best for Your Needs?

- Innovations in Bushing Technology

- How to Maintain Your Bushings and Bars

- Expert Tips on Installation and Maintenance

- Cost-Saving Benefits of High-Quality Bushings

- Conclusion: The Future of Bushings in Industrial Applications

1. What Are Bushings and Why Do They Matter?

The role of bushings in industrial applications is often underestimated. These simple yet vital components act as a buffer, reducing friction between moving parts. Whether it’s bronze bushings in heavy machinery or polyurethane bushings in automotive systems, these devices are engineered to withstand pressure, minimize wear, and protect both mechanical and structural integrity.

High-quality bushings are a key factor in ensuring that your industrial machines run efficiently with minimal maintenance. Without the right bushing, you risk frequent equipment failures, costly repairs, and operational downtime.

2. The Importance of High-Quality Bushings in Industrial Applications

Not all bushings are created equal. The quality of a bushing can drastically impact machinery performance, especially in high-stress environments. Low-quality bushings are prone to quicker wear and may lead to component failure. In contrast, high-quality bushings:

- Reduce the frequency of machine breakdowns

- Enhance operational efficiency

- Lower the overall cost of ownership by extending equipment lifespan

According to experts at Bunting Bearings, investing in premium bushings results in less wear, leading to fewer replacements and longer intervals between maintenance schedules. This is particularly crucial for industries that rely heavily on continuous operations, such as automotive, aerospace, and heavy manufacturing.

3. Different Types of High-Quality Bushings and Their Uses

Bushings come in several different forms, and understanding the various types can help you make an informed decision. Here’s an overview of the most common bushing types used in industrial applications:

Bronze Bushings

Known for their resilience and load-bearing capacity, bronze bushings are commonly used in applications with extreme pressure. They are highly resistant to corrosion and are ideal for harsh environments such as construction or mining machinery.

Polyurethane Bushings

These offer excellent shock absorption and flexibility, making them perfect for automotive suspension systems. Polyurethane bushings are also known for reducing vibration and noise, which adds to machine longevity.

Graphite Bushings

Graphite bushings offer self-lubrication, making them ideal for applications where lubrication is difficult or impossible. These bushings are commonly found in high-heat environments like the steel industry.

4. Why Durability Should Be Your Top Priority

When considering which bushing to purchase, durability should be one of your top concerns. The wear and tear caused by friction can be expensive if frequent replacements are needed. High-quality bushings offer greater wear resistance, meaning they last longer even under extreme conditions.

Durability also translates into better operational efficiency, as there will be less downtime caused by component failure. For example, bronze bushings can withstand higher loads without deforming, making them ideal for heavy-duty applications.

5. Material Selection: Which Bushing Is Best for Your Needs?

Choosing the right material for your bushing is essential for optimizing performance. Here’s a quick breakdown of the most common materials and their best use cases:

- Bronze: Best for high-load applications such as industrial presses or conveyor belts.

- Polyurethane: Ideal for shock absorption, particularly in automotive or small-scale machinery.

- Graphite: Perfect for high-temperature or low-maintenance environments.

For more detailed information, visit Bunting Bearings and explore their extensive guide on selecting the best materials for industrial bushings.

6. Innovations in Bushing Technology

The world of bushing technology is continuously evolving. New developments such as composite bushings and smart bushings are making waves in the industry. Composite bushings are made from advanced polymers that offer better resistance to wear and self-lubricating properties. These bushings are becoming increasingly popular for applications requiring minimal maintenance.

Smart bushings, embedded with sensors, are also gaining traction. These sensors monitor critical performance metrics like temperature and wear, allowing operators to perform predictive maintenance. This innovation leads to reduced downtime and extends the lifespan of the machinery.

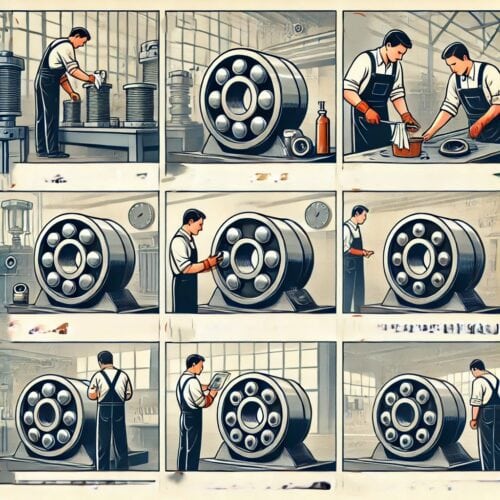

7. How to Maintain Your Bushings and Bars for Maximum Efficiency

Proper maintenance is essential for getting the most out of your high-quality bushings. Regular inspections, lubrication, and proper installation are all crucial steps in extending the life of your bushings.

- Inspect for Wear: Periodically inspect bushings for cracks, deformations, or excessive wear.

- Proper Lubrication: Ensure that bushings are adequately lubricated, especially in high-friction environments.

- Installation: Always follow manufacturer guidelines during installation to avoid misalignment.

This process is highly recommended by the experts at Bushings and Bars in order to maintain the durability you are seeking within any application.

8. Expert Tips on Installation and Maintenance

Even with the best materials, improper installation can lead to performance issues. Below are some expert tips to ensure your bushings are installed and maintained correctly:

- Check Alignment: Misaligned bushings can lead to premature wear. Use precision tools to ensure perfect alignment.

- Regular Inspections: Create a regular inspection schedule to check for wear and tear.

- Use the Right Tools: Always use manufacturer-recommended tools for installation and removal to avoid damaging the bushings.

9. Cost-Saving Benefits of High-Quality Bushings

Investing in high-quality bushings may seem costly upfront, but the long-term savings are substantial. By reducing downtime, increasing efficiency, and extending the life of your machinery, high-quality bushings pay for themselves over time.

Additionally, the reduced need for frequent replacements means lower labor and material costs. For example, bronze bushings in heavy machinery may last up to three times longer than cheaper alternatives, saving you both time and money.

10. Conclusion: The Future of Bushings in Industrial Applications

The future of bushings in industrial applications is bright, with ongoing advancements in materials and technology. As industries shift towards predictive maintenance and more durable components, high-quality bushings will continue to play a pivotal role in ensuring machinery runs efficiently and cost-effectively.

For more information on how to optimize your machinery with high-quality bushings, visit us at Bushings and Bars and our friends at Bunting Bearings for expert advice and a comprehensive selection of premium bushings and bars.