Nylon Bearing Advantages

Introduction to Nylon Bearings

Nylon bearings are an essential component in a variety of mechanical applications, known for their durability, versatility, and performance. These non-metallic bearings are made using nylon, a synthetic polymer that offers various engineering advantages over traditional materials such as steel or bronze. This article delves into the unique characteristics, advantages, applications, and custom solutions available for nylon bearings, providing valuable insights for professionals, business owners, and environmentalists alike.

The significance of nylon bearings in modern manufacturing cannot be understated. As industries increasingly seek materials that enhance efficiency, reduce maintenance costs, and provide longer life cycles, nylon bearings have emerged as a preferred choice. Their ability to operate under diverse conditions, coupled with self-lubrication capabilities, makes them ideal for applications ranging from automotive parts to HVAC systems.

Unique Advantages of Nylon Bearings

Self-Lubrication Features

One of the standout features of nylon bearings is their self-lubricating capability. Unlike traditional metal bearings that often require additional lubrication, nylon bearings are designed to maintain a low friction coefficient, which helps reduce wear and tear. This characteristic minimizes the need for regular maintenance, leading to significant operational cost savings for businesses.

Self-lubrication also plays a critical role in enhancing the longevity of machinery. By reducing friction between moving parts, nylon bearings lower the risk of overheating and mechanical failures. This is particularly beneficial in applications where continuous operation is crucial, as it ensures that machinery runs smoothly without the constant need for lubrication intervention.

Corrosion Resistance Benefits

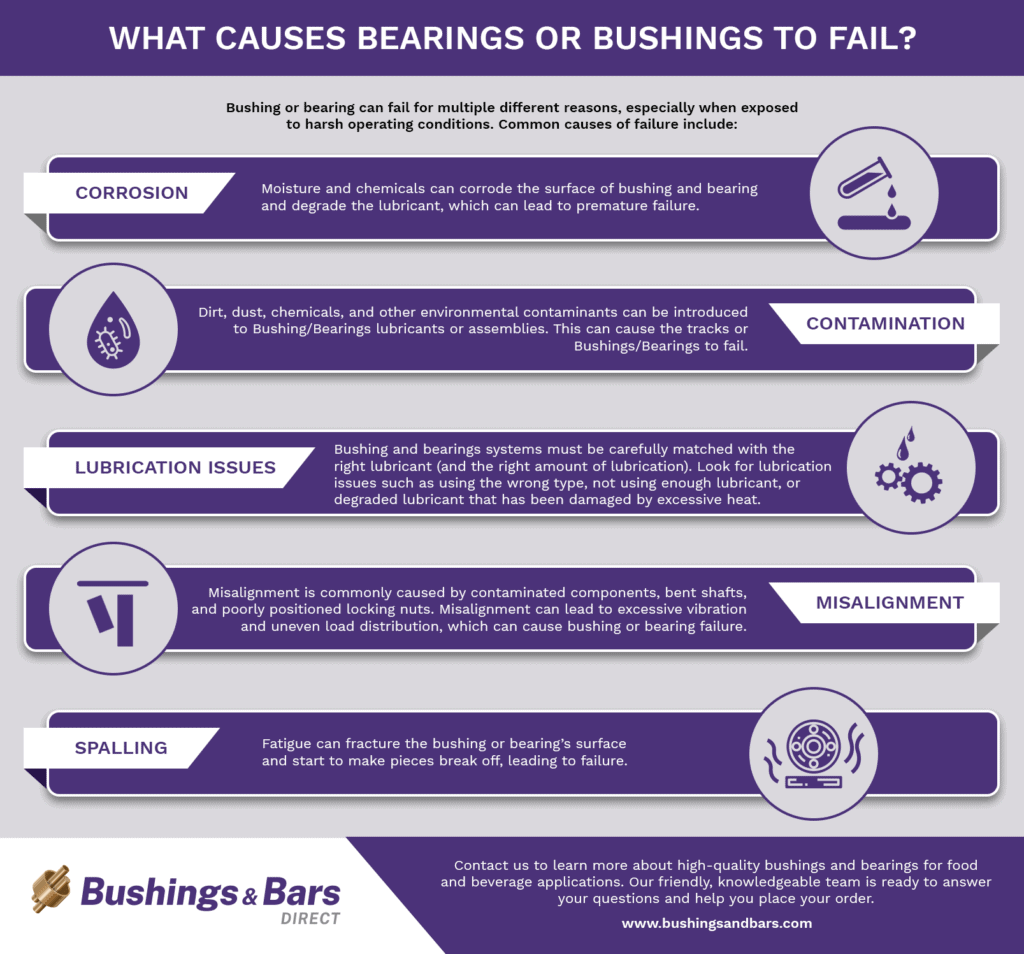

Nylon is inherently resistant to corrosion and can withstand exposure to various chemicals and environmental conditions. This property makes nylon bearings an excellent choice for applications in humid, acidic, or alkaline environments that would typically damage metal bearings. Corrosion resistance not only extends the service life of the bearings but also improves the overall reliability of the equipment they are part of.

Additionally, their resistance to various corrosive agents leads to less downtime for maintenance and repairs. Manufacturing processes that involve exposure to moisture or aggressive chemicals can benefit significantly from the use of nylon bearings, as they maintain performance without succumbing to degradation often seen in metal counterparts.

Lightweight Design Advantages

The lightweight nature of nylon bearings offers substantial advantages in terms of energy efficiency and speed. In applications where weight is a critical factor, such as in the automotive and aerospace industries, the reduction in weight can lead to enhanced fuel efficiency and overall performance. Moreover, lighter components can improve equipment dynamics, enabling faster acceleration and reduced inertia.

This advantage is not only beneficial for performance but also results in lower material costs and logistical savings. The ease of handling and installation associated with lightweight nylon bearings translates to reduced labor costs and increased productivity on manufacturing floors.

Cost-Effectiveness and Sustainability

Comparison with Metal Bearings

When comparing nylon bearings to traditional metal bearings, several cost factors come into play. Initial purchase prices for nylon bearings may be higher; however, the overall cost of ownership tends to be significantly lower. Reduced maintenance needs and longer life spans contribute to a decreased total cost of ownership, making nylon bearings more economical in the long run.

Furthermore, their self-lubricating properties eliminate the need for purchasing and applying lubricants, which adds to the financial benefits. Businesses that require reliable operation without frequent interruptions find that switching to nylon bearings can lead to substantial savings over time.

Long-Term Financial Benefits

The financial implications extend beyond just initial and maintenance costs. By incorporating nylon bearings into their operations, businesses can experience less downtime and fewer operational disruptions. This translates to increased productivity, allowing companies to focus on core activities rather than dealing with bearing-related failures.

Additionally, with their durability and resistance to wear, nylon bearings can perform well under high loads and speeds, reducing the chances of unexpected failures. This reliability can lead to more predictable budgeting and enhanced profitability, making nylon bearings an attractive option for businesses focused on long-term financial planning.

Eco-Friendly Bearings and Environmental Impact

As environmental consciousness rises, the demand for eco-friendly manufacturing practices grows. Nylon bearings are often seen as a sustainable alternative to metal bearings due to their production processes and material properties. Being lightweight contributes to lower energy consumption during transportation and operation, reducing the carbon footprint associated with equipment use.

Moreover, many nylon bearings are recyclable, further contributing to their sustainability profile. Businesses that prioritize environmental stewardship can enhance their reputations by utilizing these eco-friendly solutions, aligning with consumer expectations and regulatory requirements for sustainability.

Applications Across Industries

Automotive Industry Uses

The automotive industry has been a significant adopter of nylon bearings due to their lightweight, durable nature. They are commonly used in internal combustion engines, electric motors, and various components where efficiency and performance are paramount. For instance, nylon bearings can be found in window regulators, power steering systems, and gearboxes, providing a reliable solution that meets stringent automotive specifications.

Additionally, nylon bearings help reduce overall vehicle weight, contributing to improved fuel efficiency and lower emissions. As the industry continues to shift toward electric vehicles (EVs), the demand for lightweight, high-performance components makes nylon bearings even more relevant.

HVAC Applications

In heating, ventilation, and air conditioning (HVAC) systems, nylon bearings are utilized in fans, compressors, and pumps. Their corrosion resistance and ability to operate in humid environments make them an ideal choice for HVAC  applications, where moisture and temperature fluctuations are common.

applications, where moisture and temperature fluctuations are common.

Moreover, the self-lubricating properties of nylon bearings reduce friction in moving parts, leading to quieter operation and extended life spans for HVAC equipment. This not only benefits manufacturers but also enhances the comfort of end-users by reducing noise levels in residential and commercial environments.

Material Handling Solutions

Nylon bearings play a crucial role in material handling equipment, such as conveyor systems and robotic arms. Their lightweight design allows for smoother operation and improved energy efficiency, critical for systems that require rapid movement and precision.

As industries increasingly automate their material handling processes, the demand for reliable and efficient components will only grow. Nylon bearings’ ability to withstand heavy loads while maintaining performance makes them a preferred choice in modern material handling applications.

Expertise in Custom Nylon Solutions

Tailored Solutions for Client Needs

Many companies recognize that their specific applications may require tailored solutions; as such, manufacturers of nylon bearings often provide custom designs to meet unique technical requirements. This customization can involve varying sizes, shapes, and specifications that align with the necessary performance criteria.

By collaborating closely with engineers and designers, manufacturers can create nylon bearings that fit seamlessly into existing equipment or enhance new product designs. This flexibility allows businesses to leverage the advantages of nylon bearings while addressing specific operational challenges.

Examples of Custom Applications

Industries such as robotics, aerospace, and medical devices often require highly specialized bearings. For example, in the robotics sector, nylon bearings can be engineered to reduce weight while providing high load capacity and precision movement. In the medical field, custom-sized nylon bearings can be designed to fit in complex instruments, ensuring smooth operation in critical applications.

These examples illustrate how custom nylon solutions not only enhance operational efficiency but also open doors to innovation across various industries. By investing in tailored bearing solutions, companies can ensure that they stay competitive in a rapidly evolving marketplace.

Conclusion

Recap of Key Advantages

In summary, nylon bearings offer a myriad of advantages, including self-lubrication, corrosion resistance, lightweight design, and cost-effectiveness. These features make them suitable for various industries, including automotive, HVAC, and material handling, while also contributing to sustainability efforts. The ability to customize nylon bearings further enhances their appeal, allowing businesses to meet specific needs and improve operational efficiency. According to Materials Today, nylon is a highly durable material used in industrial applications.

Call to Action for Industry Professionals

As industries continue to evolve, embracing innovative solutions like nylon bearings can provide a competitive edge. By considering the advantages of nylon bearings in your operations, you can enhance performance, lower costs, and contribute to sustainability efforts in your manufacturing processes.

FAQs

What are nylon bearings made from?

Nylon bearings are primarily made from nylon, a synthetic polymer known for its strength, durability, and resistance to wear and corrosion.

How do nylon bearings compare to metal bearings?

Nylon bearings offer advantages in terms of weight, self-lubrication, and corrosion resistance, often resulting in lower maintenance costs and longer lifespan compared to metal bearings.

Are nylon bearings suitable for high-load applications?

Yes, nylon bearings can be engineered to handle high loads while maintaining performance, making them suitable for various applications such as automotive and industrial machinery.

Can nylon bearings be used in corrosive environments?

Absolutely. Nylon bearings are resistant to corrosion from chemicals and moisture, making them ideal for use in harsh environments.

What customization options are available for nylon bearings?

Manufacturers can provide custom nylon bearings tailored to specific sizes, shapes, and performance characteristics to fit unique application requirements.

10 Reasons Why High-Quality Bushings for Industrial Applications Improve Durability & Efficiency