The food and beverage industry operates under a number of requirements to ensure all products are free from contamination and safe to consume. This includes regulations for cleanliness and sanitation as well as the use of proper materials that won’t leach toxic substances or shed particles into the food. Every component of production, from the room the food is produced in right down to the bushings and bearings for food and beverage equipment, must meet these strict standards to ensure safety and suitability.

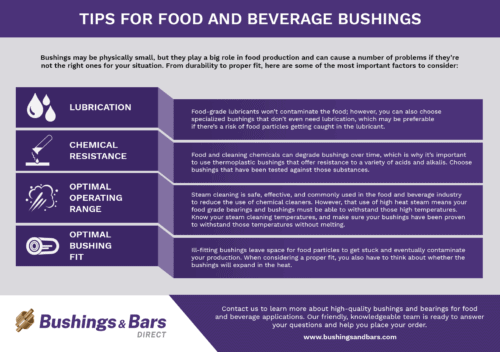

Tips for Food and Beverage Bushings

Bushings may be physically small, but they play a big role in food production and can cause a number of problems if they’re not the right ones for your situation. From durability to proper fit, here are some of the most important factors to consider:

- Lubrication: Food-grade lubricants won’t contaminate the food; however, you can also choose specialized bushings that don’t even need lubrication, which may be preferable if there’s a risk of food particles getting caught in the lubricant.

- Chemical Resistance: Food and cleaning chemicals can degrade bushings over time, which is why it’s important to use thermoplastic bushings that offer resistance to a variety of acids and alkalis. Choose bushings that have been tested against those substances.

- Optimal Operating Range: Steam cleaning is safe, effective, and commonly used in the food and beverage industry to reduce the use of chemical cleaners. However, that use of high heat steam means your food grade bearings and bushings must be able to withstand those high temperatures. Know your steam cleaning temperatures, and make sure your bushings have been proven to withstand those temperatures without melting.

- Optimal Bushing Fit: Ill-fitting bushings leave space for food particles to get stuck and eventually contaminate your production. When considering a proper fit, you also have to think about whether the bushings will expand in the heat.

Bearings and bushings are available in a variety of sizes and materials, from bronze to nylon, PTFE, and more, to meet different industry requirements—as well as different requirements within the food industry itself. You may have to consider what type of food or beverage you’re producing, as well as the environmental conditions, equipment size and requirements, and more.

Applications of Food and Beverage Bushings

There are a lot of moving parts in a food production facility, which means food grade bushings are needed throughout food and beverage manufacturing, processing, and handling:

- Processing equipment

- Blenders and mixers

- Ice machines

- Picking and weighing equipment

- Conveyor belts

- Ovens

- And more

These bushings must be built to withstand specific environmental conditions and address common food production problems and challenges. The right bushings improve food safety, prolong equipment life, decrease unexpected repairs and downtime, and increase productivity. In the end, they improve your bottom line.

Why Partner with Bushing and Bars?

With years of experience and extensive capabilities, we understand and can meet the strict regulations in the food and beverage industry. Thermoplastic bushings are a popular choice, given their heat and chemical resistance, and we can help you choose bushings of the right size, fit, and material for your application. Whether you need food grade bushings that can withstand a heavy load or resist moisture, excessive wear, or high temperatures, we’ll work closely with you to understand your requirements and provide the ideal solution. With our streamlined process, massive inventory, and close relationships with the industry’s top manufacturers, we can help you get the products you need, when you need them.

Contact us to learn more about high-quality bushings and bearings for food and beverage applications. Our friendly, knowledgeable team is ready to answer your questions and help you place your order.